It has been the one bug bear of mine. That little niggle about

airgunning. The tie that keeps me reliant on the world of money and the

marketplace.

I speak of ammunition, its consumption and its loss.

We use a lot of pellets!

Accuracy demands that each pellet is near identical in shape and weight, and soft (for the rifling). Killing cleanly requires the material, after accuracy is obtained, to still pack a punch, thus a metal is deemed best.

It is therefore safe to say this means a man in the woods cannot extract or find the materials from the surroundings without mining the ore (if it even exists locally), smelting, casting, moulding, and swaging.

Unfortunately, if one is to stay safe from harassment, bow hunting, despite its 'renewable' ammo, is not an option on this island of ours, and catapults firing stones that are rarely uniform is a challenge I have yet to master.

On and off I researched various methods of banging out homemade ammo, but none were acceptable;

Corbin Pellet Presses and Swaging dies -Too expensive, too bulky and hardly cost effective to have shipped from the US of A.

L.E.M Spitzer moulds - poor accuracy results, becoming rare, none found in .177, production long ceased.

But lo! Whilst browsing for airgun bargains I came across an advert for a product aptly named "Airgun Pellet Maker". A chap had knocked up a prototype and posted a video of it on YouTube (I remember seeing it when it was first posted). He finally bowed to demand and has begun manufacturing them for sale.

He also lived locally so I popped across and we did a deal on a set. One .22 swager, one .177 swager and a dual calibre casting block.

That was on a Monday when the weather was poor and work was called off. I didn't get an opportunity to play until yesterday.

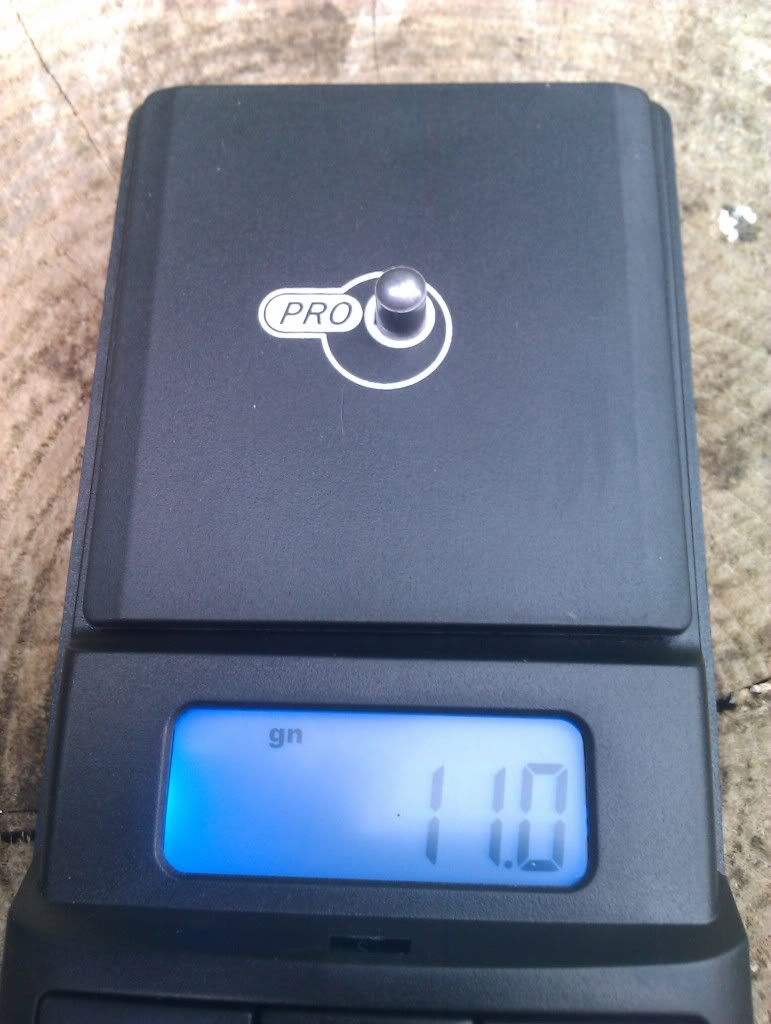

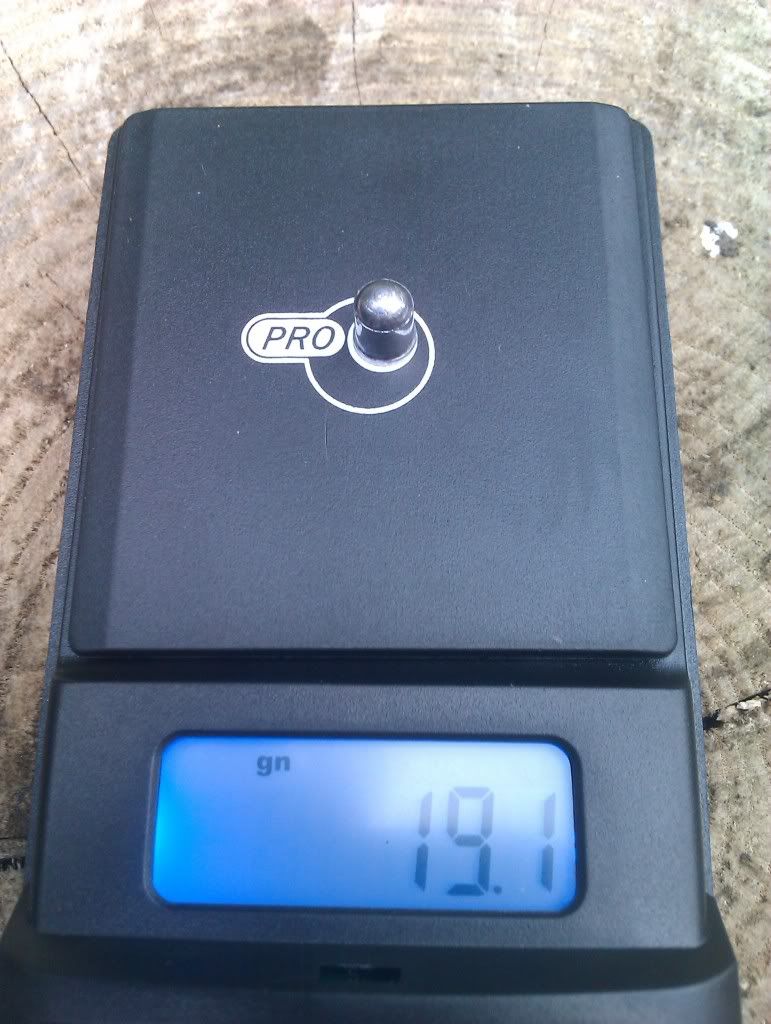

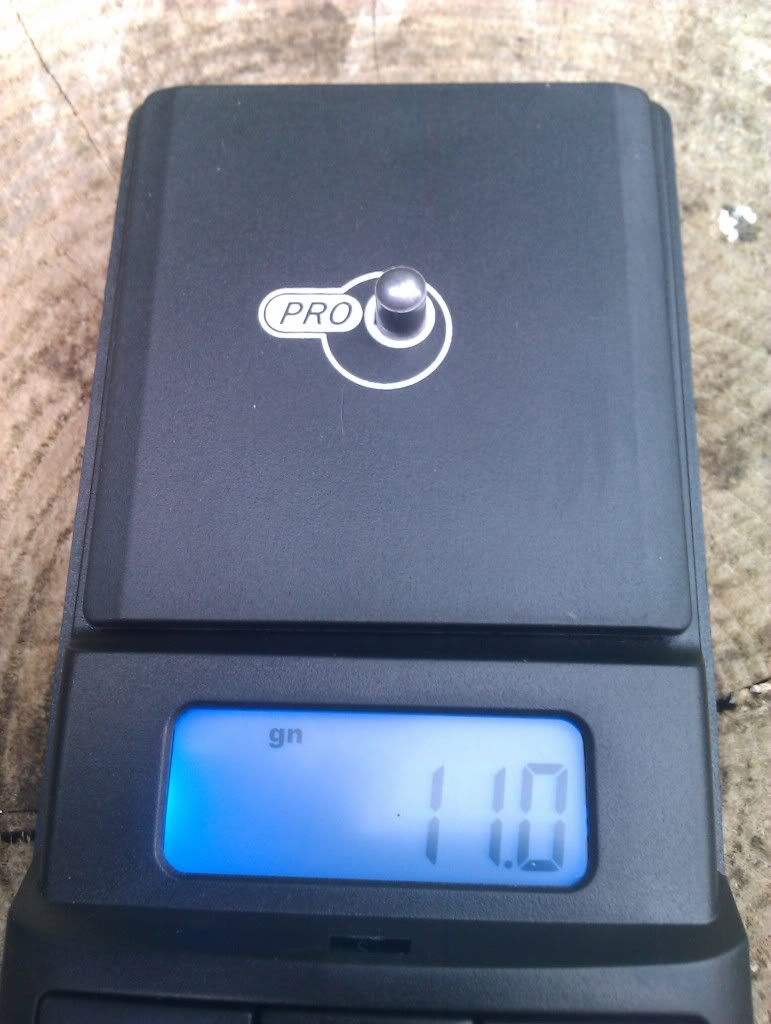

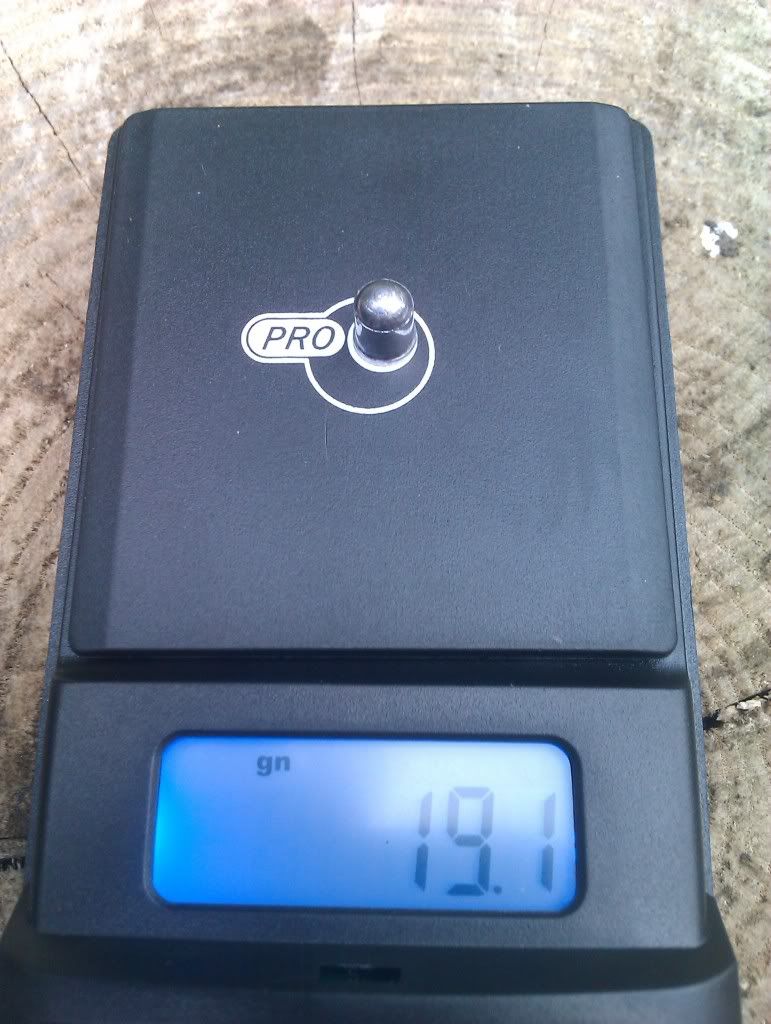

I was gifted some blanks to press and play with so I thought I'd do those and see what sort of weight the products were and their consistency on my new junkie scales bought for the job. Each were on the dot identical.

.177;

.22;

Now being as I'm using a springer, I've turned the weight of the .22s down to 18.4gr. The .177 I'm happy with as I want the punch.

The measurements include the tail flair, each fit beautifully in the barrels of the TX200 and TH208.

Pics of my play time.

Casting Block and eBay Lead Ladle;

The Blanks;

The Melting Pot;

The Finished Pellets;

The 'Workstation';

The lead was obtained from the old roof of this house I'm working on. The swager is to the right of the casting block seen in two parts. I intend to do a bit of a review of it with better pics outlining the method and process.

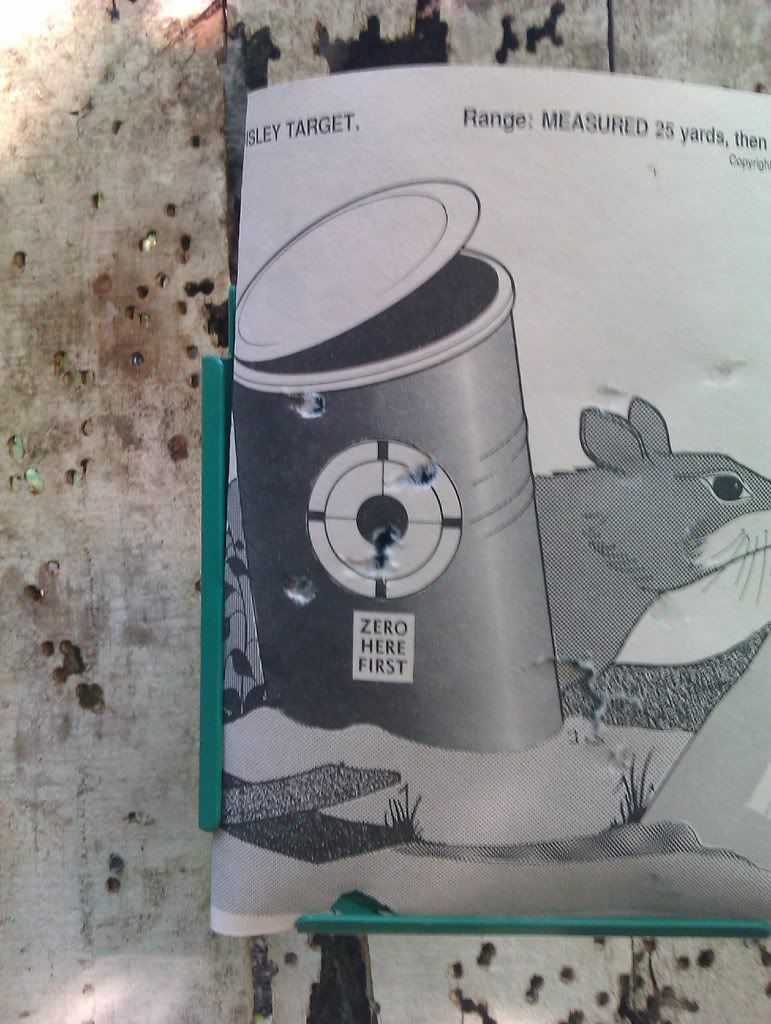

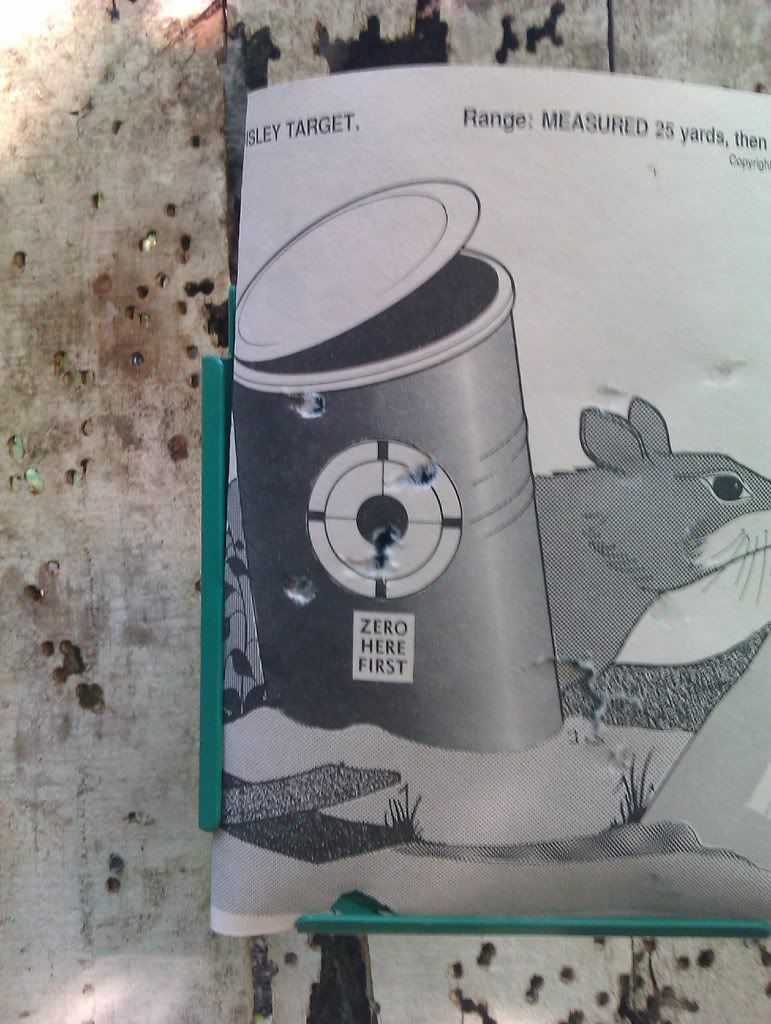

First test through the tx200 .177 10 yards.

Those two flyers, I think, were me tweaking the scope, zeroing as I went, and experimenting with holds. I was pretty impressed

Melting the old lead In a pellet tin on an old SMA Dried Milk Can using charcoal made in the woodburner;

Ran out of charcoal and had to use wood. I needed more oomph so...;

The process is alot of fun. Not everyone's cup of tea, but for me the value is more in the capability. Both the ability of recycling my shot, and forming it.

Hoorah!

Now to find the lead mine....

I speak of ammunition, its consumption and its loss.

We use a lot of pellets!

Accuracy demands that each pellet is near identical in shape and weight, and soft (for the rifling). Killing cleanly requires the material, after accuracy is obtained, to still pack a punch, thus a metal is deemed best.

It is therefore safe to say this means a man in the woods cannot extract or find the materials from the surroundings without mining the ore (if it even exists locally), smelting, casting, moulding, and swaging.

Unfortunately, if one is to stay safe from harassment, bow hunting, despite its 'renewable' ammo, is not an option on this island of ours, and catapults firing stones that are rarely uniform is a challenge I have yet to master.

On and off I researched various methods of banging out homemade ammo, but none were acceptable;

Corbin Pellet Presses and Swaging dies -Too expensive, too bulky and hardly cost effective to have shipped from the US of A.

L.E.M Spitzer moulds - poor accuracy results, becoming rare, none found in .177, production long ceased.

But lo! Whilst browsing for airgun bargains I came across an advert for a product aptly named "Airgun Pellet Maker". A chap had knocked up a prototype and posted a video of it on YouTube (I remember seeing it when it was first posted). He finally bowed to demand and has begun manufacturing them for sale.

He also lived locally so I popped across and we did a deal on a set. One .22 swager, one .177 swager and a dual calibre casting block.

That was on a Monday when the weather was poor and work was called off. I didn't get an opportunity to play until yesterday.

I was gifted some blanks to press and play with so I thought I'd do those and see what sort of weight the products were and their consistency on my new junkie scales bought for the job. Each were on the dot identical.

.177;

.22;

Now being as I'm using a springer, I've turned the weight of the .22s down to 18.4gr. The .177 I'm happy with as I want the punch.

The measurements include the tail flair, each fit beautifully in the barrels of the TX200 and TH208.

Pics of my play time.

Casting Block and eBay Lead Ladle;

The Blanks;

The Melting Pot;

The Finished Pellets;

The 'Workstation';

The lead was obtained from the old roof of this house I'm working on. The swager is to the right of the casting block seen in two parts. I intend to do a bit of a review of it with better pics outlining the method and process.

First test through the tx200 .177 10 yards.

Those two flyers, I think, were me tweaking the scope, zeroing as I went, and experimenting with holds. I was pretty impressed

Melting the old lead In a pellet tin on an old SMA Dried Milk Can using charcoal made in the woodburner;

Ran out of charcoal and had to use wood. I needed more oomph so...;

The process is alot of fun. Not everyone's cup of tea, but for me the value is more in the capability. Both the ability of recycling my shot, and forming it.

Hoorah!

Now to find the lead mine....

Love the resourcefulness! Keep up the great Blog!

ReplyDeleteUntil I read this I didn't really give my pellets a second thought,excellent information

ReplyDeleteHave you done any further testing on these pellets ??

ReplyDeleteI'm looking at this for my own airrifles but havent found any real accuracy tests/results.

Excellent website you have here: so much cool information!.. Top Rated Pellet Smokers

ReplyDelete